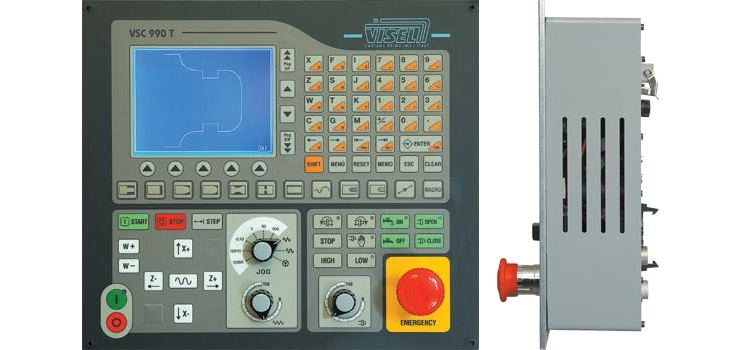

Numeric control mod. VSC 990 M-T for milling and turning |

VERSIONS: 3 - 4 - 5 axis + spindle

Linear, circular, helicoidal interpolation

|

|

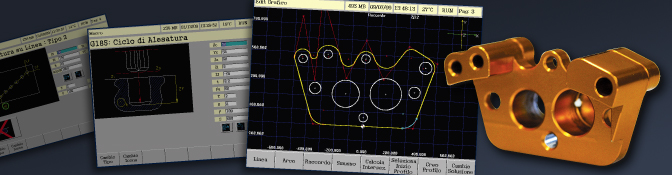

VSC990 T for turning

|

|

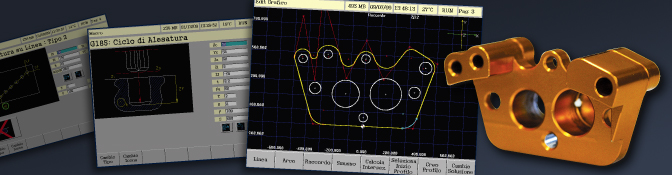

VSC990 M for milling

|

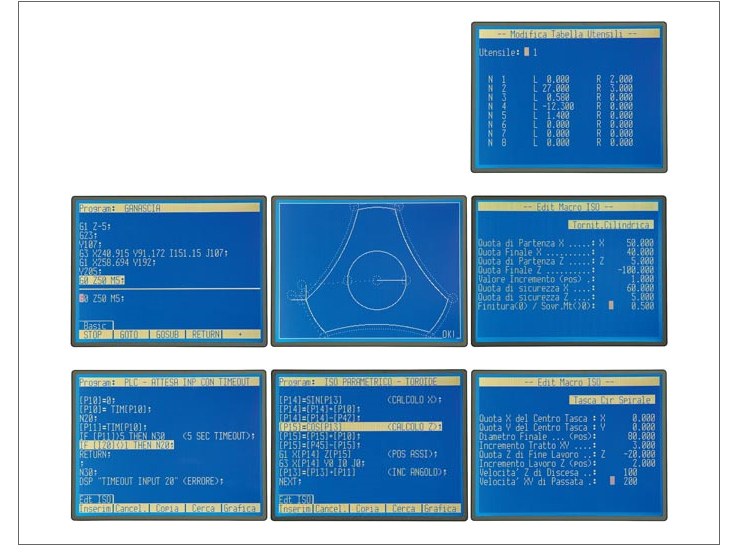

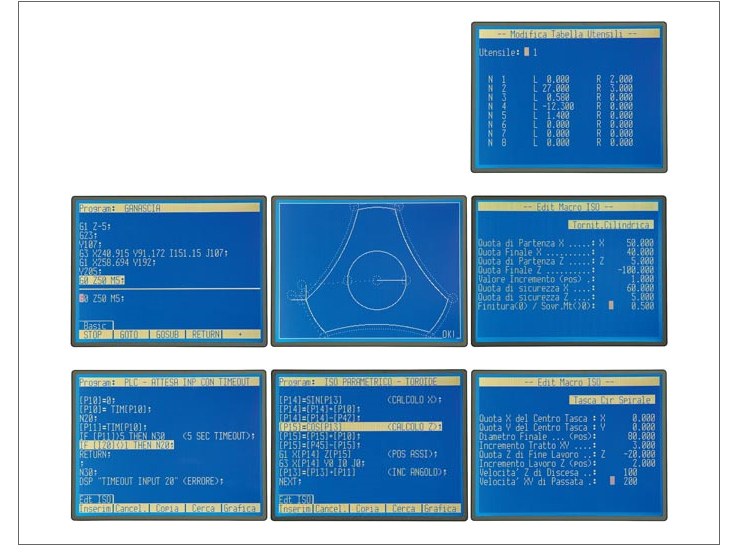

VSC 990 SPECIFIC FUNCTIONS

- ISO standard programming

- ISO PARAMETRIC programming

- Fixed cycles or macro programming

- Auto-learning programming

- RS232 programming

- Programs receipt from post-processor CAM

- File programs storing with alphanumeric comments (500 Kb)

- Manual execution of fixed cycle directly from menu selected by keys with icon

- DNC work execution with PC

- Management of electronic handwheel

- Impulse and continuos Jog with speed or direct shift

- Tool magazine or tool table (24 tools)

- Automatic change range

- 24 program origins

- Preset dimension with specific shift

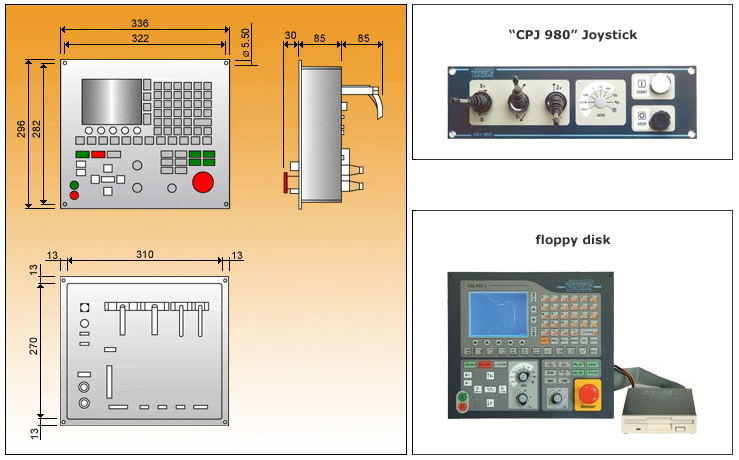

- Floppy disk (optional)

- Control with potentiometer of axes override + spindle speed

- Percentage graphic display of spindle torque during the work

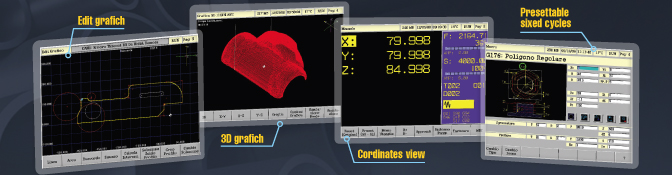

- 2D graphic display with zoom of produced profiles and tool run

- Piece counter display – work time with counter preset

- Change range activation, refrigerator, tool clamping-unclamping from program and keys

- Language selection (I , GB , F) menu

|

VERSION: 990-M MILLING

- Control of speed and position spindle axes (rigid tapping)

- Fourth axes (C axes) for continuos rotary table included

|

VERSION: 990-T TURNING

- Control of speed and position spindle axes

- Position control of motorized tailstock

|

SPECIFY MACRO PROGRAMMING

|

990-M VERSION (Milling)

Macro function included fixed cycles

- G70 Drilling on line

- G71 Drilling on reticle

- G72 Drilling on circumference

- G73 Levelling and runout rectangular and greek pocket

- G74 Eyelet – linear key

- G75 Eyelet – key on arc/circumference

- G76 Creation of regular polygons

- G77 Profile mirror copy

- G78 Rotation/Translation profile

- G79 Step work for blades and rack

- G81 Drilling and centering

- G82 Thread with helicoidal interpolation

- G84 Rigid tapping

- G85 Reaming

- G86 Boring

- G61 Creation of circular relief in shape

- G87 Spiral runout of a rectangular pocket

- G88 Spiral runout of a circular pocket

- G89 Hole widening

- G62 Thread at variable steps with rotary table (on cylinders)

|

990-T VERSION (Lathe)

Macro function standard fixed cycles

- G60 Cylindrical turning

- G61 Cycle of facing

- G63 Cycle of conic turning

- G64 Cycle of ray

- G65 Cycle of swell

- G66 Cycle for throat/groove

- G88 Cycle for points profiles creation

- G67 Cycle of thread

- G68 Cycle of drilling with discharge

- G69 Cycle of Tapping

|

OTHER FUNCTIONS

- FOR-NEXT cycles for multiple repetition

- GOT-GOSUB functions for jump to multiple under-programs

- Waiting function: WAIT

- Temporary STOP function (with restart)

|

|

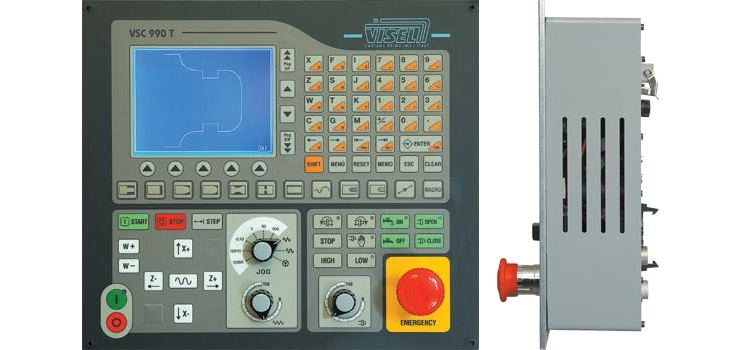

HARDWARE FEATURES

- 06 analogical axes output (+/- 10 Vcc) opto-isolate

- 03 digital axes output (square waves 12 Vcc PNP)

- 06 differential encoder input line driver

- 02 analog input (0/+10 Vcc) opto-isolate

- 32 Digital input 24 Vcc opto-isolate PNP

- 20 digitals output 24 Vcc opto-isolate PNP

- 01 Serial port RS232

- Optional: Floppy disk interface (output)

- 01 extensible electronic handwheel input mod. EKV

- 01 opto isolate output for remote control Jog

- Integrated PLC (for user programming)

- Power supply 90-279 Vca (40W)

- Polyester tight keyboard

- Back illuminate display LCD TFT 6”

- Included emergency pushbutton

- Ignitions/power off: motors power, cooler, spindle rotation, change range, jog include in the keyboard

- Jog selector, spindle speed and override include in the key board

|

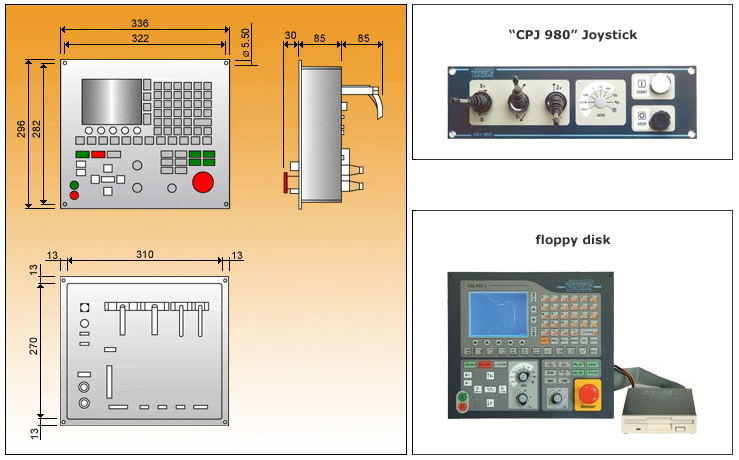

OPTIONALS

- Floppy disk interface

- Remote electronic handwheel "EKV"

- "CPJ 980" Joystick panel

- IN/OUT expansion: + 32 input, 20 output

handwheel "EKV"

|

DIMENSIONI

|