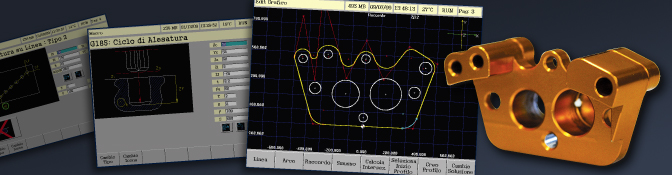

High performance in Milling

The new VSC 1040 DM CNC was designed for all milling machining on vertical & horizontal machining centres and milling machines. Extremely complete,

simple and intuitive to use, it has many options and macros that can be used to make dies and complex workpieces.

Typically used together with an external CAM, programs are loaded over a LAN network or from a USB flash drive. Files can also be directly imported in

.DXF format and machining can be performed using specific macros.

The real-time dual processor on the VSC 1040 DM CNC can process blocks in 1 ms, and is capable of executing 1000 blocks/second with a look-ahead of 400

blocks.

A special algorithm was integrated to optimize trajectories, thus favouring machining speed and high-speed profile execution. It’s a multi-tasking system

and allows other operations to be executed (creating programs, downloading/uploading programs, etc.) during machining.

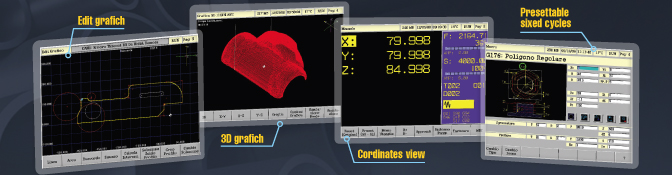

Powerful 3D graphics show the finished workpiece and machining simulation can be used to display how the piece is machined, including estimated

timeframes and different colours for each tool.

A special set of commands was introduced for complex 5-axis machining (managing kinematic motion, controlling dynamic RTCP, managing tilted planes,

etc.).

|

FEATURES

- Multi language select menù

- Possibility of programming during processing (MULTITHREADS)

- Hardware PC base embedded, dual processor, real-time

- 4 axis/ 5axis + spindle (control in position) management

- Linear, circular, helicoidal, interpolations

- Standard flash program memory 1 Gbyte

- UBS - Pen Drive interface

- ETERNETH interface connection

- CAN-BUS modules connection

- ISO - Parametric ISO standard programming

- Fixed cycles (Macro) conversational programming

- CAD file import .DXF

- Grafic Edit (mini CAD-CAM included) with ISO profile converted

- Cycles (Macro) calling and execution direct from single key with icon or menù

- MACROMAKER PC program for build and import Macro to CNC by yourself (optional)

- Import and execution file from CAM

- Programs nesting management (40)

- Origins table (100 origins) managements

- MDI function with single block execution

- Advance 250 Tools table management (tools torque controls)

- 3D or single plane graphic view (with zoom function)

- Scale factor setting on each axes

- Roto-translation of view axis

- 3D dinamic graphic simulation (with tool show)

- Dinamic graphic simulation piece during the cycle (real-time)

- Graphic-percentual view of spindle torque

- Estimate total time piece execution + pieces counter function

- “TOOL INSPECTOR” function with tool repositioning and restart of the cycle from a point

- MECHATROLINK (Yaskawa) interface (optional)

- EtherCAT interface (optional)

- PLC management included of jog key, selector and override

- Allarm diagnostic data base

- Oscilloscope function for set up axis

- Logic Analizzator function for monitor In/Out states

|